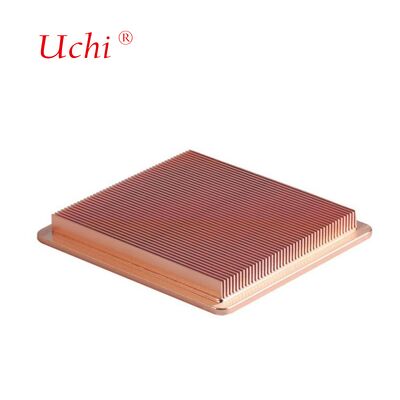

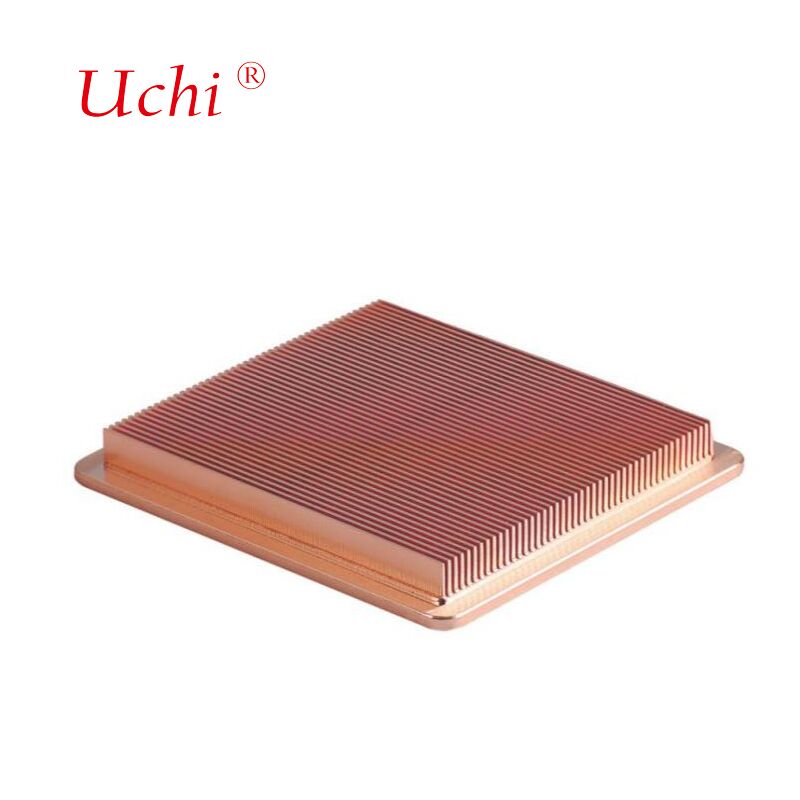

Mini centralna jednostka przetwarzania (CPU) systemu chłodzonego powietrzem

Szczegóły Produktu:

| Miejsce pochodzenia: | Dongguan, Guangdong, Chiny |

| Nazwa handlowa: | Uchi |

| Orzecznictwo: | SMC |

| Numer modelu: | radiator z zaokrąglonymi żebrami 02 |

Zapłata:

| Minimalne zamówienie: | 100szt |

|---|---|

| Cena: | negocjowalne |

| Zasady płatności: | T/T, PayPal, Western Union, MoneyGram |

| Możliwość Supply: | 50000000 pCS miesięcznie |

|

Szczegóły informacji |

|||

| Stopień: | Seria 6000 | Usługa przetwarzania: | Cięcie, wykrawanie, rozwijanie, gięcie, wiercenie |

|---|---|---|---|

| Hartować: | T3 ~ T8 | Uszczelka: | karton WOREK PE |

| Tolerancja: | ±1% | Standard: | Średniej i wysokiej jakości aluminiowy radiator |

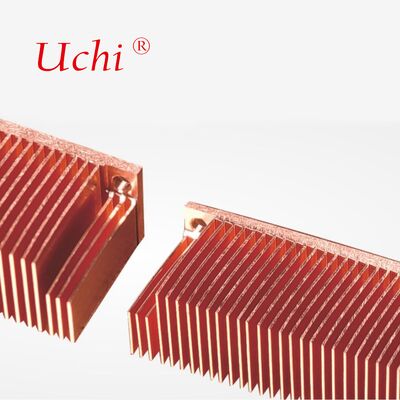

| Głęboki proces: | Obróbka CNC | Tworzywo: | Miedź Aluminium |

| Rozmiar opakowania: | 42,5*33*18CM | Waga produktu: | 0,187 kg |

| Podkreślić: | Mini CPU chłodzony powietrzem radiator cieplny,Kompaktny system chłodzenia procesora,Chłodnicy CPU chłodzone powietrzem |

||

opis produktu

Miniaturowy system chłodzony powietrzem Radiator jednostki centralnej (CPU).

Nasz mini, chłodzony powietrzem radiator procesora jest wyposażony w zaawansowaną technologię zarządzania temperaturą, zaprojektowaną z myślą o optymalnej wydajności i niezawodności w wymagających zastosowaniach.

Cechy konstrukcyjne i technologia

Konstrukcja grzejnika w stylu harmonijkowym maksymalizuje powierzchnię dzięki precyzyjnie wygiętym cienkim aluminiowym płytom, podczas gdy łopatki grzejnika wirowego są strategicznie nachylone, aby poprawić cyrkulację powietrza i efektywność rozpraszania ciepła.

- Doskonałość materiału:Konstrukcja ze stopu aluminium zapewnia optymalny stosunek ceny do wydajności przy doskonałej przewodności cieplnej

- Zwiększona powierzchnia:Rozszerzona powierzchnia konwekcyjna zapewnia doskonałe odprowadzanie ciepła poprzez zoptymalizowany kontakt z powietrzem

- Inżynieria precyzyjna:Cienka konstrukcja podstawy zapobiega oporowi termicznemu, a gęste rowki odchylające maksymalizują powierzchnię kontaktu z powietrzem

Zaawansowane zastosowania produkcyjne

Zaawansowane rozwiązania termiczne dla najnowocześniejszych gałęzi przemysłu wymagających doskonałego zarządzania ciepłem:

- Produkcja półprzewodników i chipów:Pokonywanie ograniczeń przewodności cieplnej w zaawansowanych technologiach pakowania, w tym układaniu w stosy 3D

- Obliczenia AI i centra danych:Rozwiązanie problemu rosnącej gęstości strumienia ciepła, która stanowi wyzwanie dla tradycyjnych metod chłodzenia

- Przemysł lotniczy:Specjalistyczne rozwiązania do środowisk o ekstremalnych temperaturach i warunkach próżni, gdzie konwekcja jest ograniczona

Zastosowania codzienne

Niezawodne rozwiązania w zakresie zarządzania ciepłem dla produktów konsumenckich i komercyjnych:

- Urządzenia cyfrowe:Wewnętrzne moduły chłodzące do komputerów, telefonów komórkowych i konsol do gier

- Sprzęt komunikacyjny:Duże radiatory zapewniające stabilność w systemach szybkiej transmisji danych

- Sprzęt AGD:Efektywne przenoszenie ciepła w sprężarkach i agregatach skraplających

- Oświetlenie LED:Konstrukcje termiczne zapewniające skuteczność świetlną i dłuższą żywotność

- Nowe pojazdy energetyczne:Zaawansowane systemy chłodzenia cieczą zapewniające optymalne temperatury pracy

Możliwości produkcyjne

Zaawansowana infrastruktura sprzętowa

Nasz warsztat formowania charakteryzuje się wszechstronnymi możliwościami produkcyjnymi przy użyciu najnowocześniejszego sprzętu:

- 22 maszyny elektroerozyjne (EDM), w tym 2 maszyny MAKINO do obróbki lustrzanej

- 9 wycinarek drutowych EDM (3 Seibu i 1 Sodick importowane z Japonii)

- 7 elektrodrążarki, 10 szlifierek, 2 frezarki i 1 tokarka

| Specyfikacja | Pojemność |

|---|---|

| Rozmiar stołu | 500×350 mm |

| Szybka prędkość przesuwu | 5000 mm/min |

| Maksymalna masa przedmiotu obrabianego | 500 kg |

| Maksymalna waga elektrody | 50 kg |

Technologia obróbki precyzyjnej

Wykorzystując technologie SuperSpark4 i Intelligent Expert System (IES) do zaawansowanego adaptacyjnego zasilania i kontroli skoku, zapewniając stabilne procesy EDM i doskonałą precyzję obróbki. Nasze technologie generatorów ultrapowierzchniowych i ultrakrawędziowych zapewniają doskonałe wykończenie powierzchni i jakość metalurgiczną.

Aplikacje produktów

Zapewnienie jakości

Utrzymujemy rygorystyczne standardy jakości dzięki kompleksowemu sprzętowi badawczemu:

- 1 współrzędnościowa maszyna pomiarowa

- 1 projektor

- 2 maszyny do testowania wody pod wysokim ciśnieniem

- 4 maszyny do badania odporności termicznej

- 2 maszyny do badania wycieków cieczy

Zaangażowanie w obsługę klienta

- Szybka reakcja na wszystkie zapytania

- Konkurencyjne ceny przy gwarantowanej jakości

- Efektywne planowanie produkcji

- Optymalne rozwiązania transportowe

- Kompleksowe wsparcie techniczne

Często zadawane pytania

Jesteś firmą handlową lub producentem?

Jesteśmy profesjonalnym producentem radiatorów i płyt do chłodzenia wodą, posiadającym duże doświadczenie i silny zespół techniczny, charakteryzujący się zautomatyzowaną i zmechanizowaną produkcją.

Czy eksportowałeś już towary i do jakich regionów?

60% naszej całkowitej produkcji eksportujemy do Japonii, Indii, Wielkiej Brytanii, Kanady, USA i Brazylii.

Ilu masz pracowników?

Około 100 pracowników w działach sprzedaży, zakupów, inżynierii, kontroli jakości, magazynie i produkcji.

Czy możesz dostarczyć próbki, jeśli zgadzamy się z projektem?

Tak, dostarczamy próbki do potwierdzenia przed masową produkcją, wraz z rysunkami technicznymi, jeśli jest to wymagane.

Jakie metody pakowania stosujecie?

Indywidualne opakowanie zawierające zwykłe kartony i szczelną tkaninę lub drewniane kartony dla optymalnej ochrony podczas transportu.

Czy zapewniacie wsparcie techniczne w przypadku problemów z produktami?

Wszystkie produkty są w pełni sprawdzane przed wysyłką. W przypadku jakichkolwiek problemów zapewniamy natychmiastowe rozwiązania techniczne.

Chcesz dowiedzieć się więcej o tym produkcie