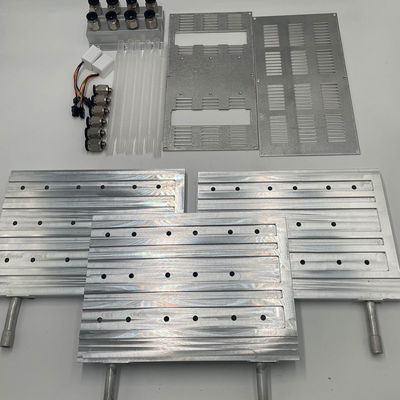

Lutowane Płyty Chłodzące Cieczą z Rurkami w Płycie Chłodzącej Powierzchni Chłodzonej Cieczą

Szczegóły Produktu:

| Miejsce pochodzenia: | Dongguan, Guangdong, Chiny |

| Nazwa handlowa: | Uchi |

| Orzecznictwo: | SMC |

| Numer modelu: | Płyta chłodząca 46 |

Zapłata:

| Minimalne zamówienie: | 100pcs |

|---|---|

| Cena: | negocjowalne |

| Zasady płatności: | T/T, PayPal, Western Union, MoneyGram |

| Możliwość Supply: | 50000000 pCS miesięcznie |

|

Szczegóły informacji |

|||

| Tworzywo: | Stop aluminium | Ciśnienie robocze: | Co najmniej 1 bar |

|---|---|---|---|

| Wykończenie powierzchni: | Wykończenie młyna lub anodowanie | Rozmiar pojedynczego pakietu: | 45X40X10cm |

| Pojedyncza waga brutto: | 5.000 kg | Gwarancja: | 1 rok |

| Podkreślić: | lutowana płyta chłodząca cieczą,chłodzenie cieczą z rurkami w płycie,radiator powierzchni chłodzonej cieczą |

||

opis produktu

Nasze lutowane radiatory z zimną płytą charakteryzują się wyjątkową wydajnością przewodzenia ciepła i zwartą, trwałą konstrukcją odporną na korozję i wysokie ciśnienie. Te lekkie płyty chłodzące, zaprojektowane z myślą o złożonych źródłach ciepła, zapewniają równomierne rozpraszanie ciepła, aby niezawodnie spełniać wymagania dotyczące zarządzania ciepłem w zaawansowanych urządzeniach elektronicznych.

| Przedmiot | Wartość |

|---|---|

| Stan | Nowy |

| Obowiązujące branże | Elektronika, produkcja, energia, budownictwo, żywność i napoje i nie tylko |

| Waga | 2 kg |

| Miejsce pochodzenia | Chiny |

| Nazwa marki | Uchi |

| Typ | Części sprężarki chłodniczej |

| Tworzywo | Stop aluminium |

| Metoda chłodzenia | Chłodzenie cieczą |

| Ciśnienie robocze | Co najmniej 1 bar |

| Wykończenie powierzchni | Wykończenie młyna lub anodowanie |

| Płyn chłodzący | Woda dejonizowana, glikol i woda hamowana, płyn dielektryczny |

| Gwarancja | 1 rok |

Nasz proces lutowania próżniowego łączy płyty aluminiowe przy użyciu spoiwa o niższej temperaturze topnienia niż materiał podstawowy, tworząc wyjątkowo mocne połączenia bez resztkowego topnika korozyjnego. Ta zaawansowana technologia zapewnia równomierne ogrzewanie, precyzyjną kontrolę temperatury i eliminuje konieczność czyszczenia po obróbce, minimalizując jednocześnie zniekształcenia części.

- Lasery i sprzęt medyczny

- Chłodzenie zestawu akumulatorów EV

- Energoelektronika i urządzenia napędowe silników

- Mikrofalowe systemy transmisji 5G

- Systemy energii odnawialnej

- Systemy półprzewodnikowe IGBT i mocy

- Centra danych i zastosowania w energetyce przemysłowej

- Systemy obronne i awionika

- Ogniwa paliwowe i systemy trakcyjne

Nasz zakład produkcyjny obejmuje 25 maszyn CNC, 10 maszyn do tłoczenia, 2 zgrzewarki tarciowe, 2 duże dmuchawy termiczne, 4 maszyny do cięcia drutem, 2 maszyny iskrowe, 4 frezarki i 3 szlifierki.

Utrzymujemy rygorystyczne standardy jakości dzięki 1 współrzędnościowej maszynie pomiarowej, 1 projektorowi, 2 maszynom do testowania wysokiego ciśnienia wody, 4 maszynom do testowania odporności termicznej i 2 maszynom do testowania wycieków cieczy.

- Szybka reakcja na wszystkie zapytania

- Konkurencyjne ceny przy gwarantowanej jakości

- Efektywne planowanie produkcji

- Optymalne rozwiązania transportowe

- Kompleksowe wsparcie techniczne