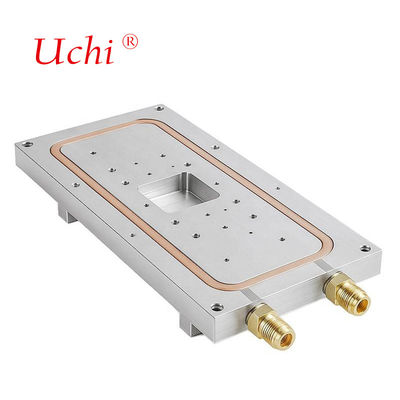

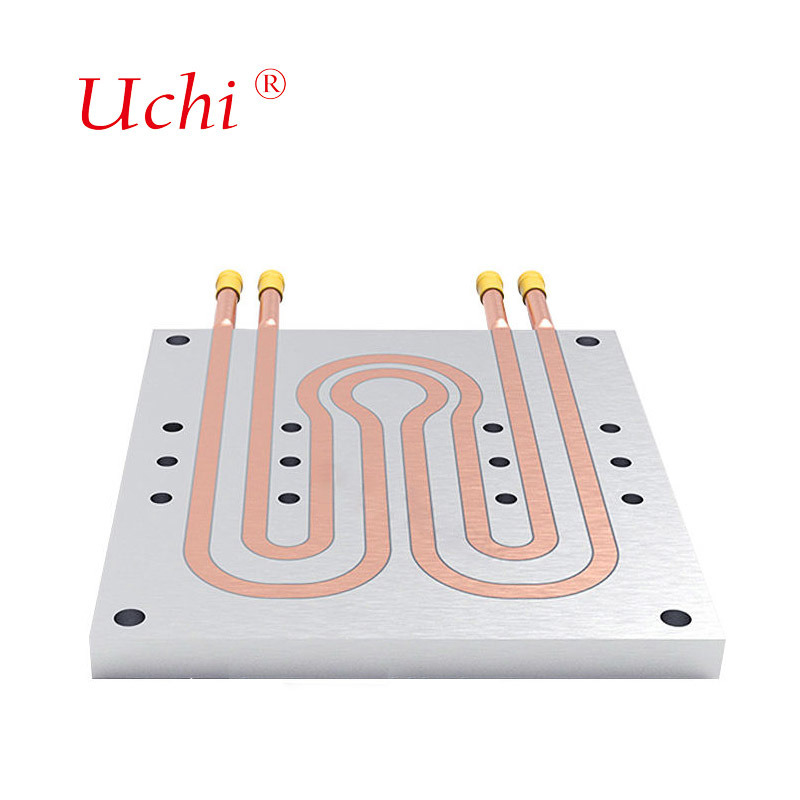

Miedziany radiator chłodzony wodą z rurkami

Szczegóły Produktu:

| Miejsce pochodzenia: | Dongguan, Guangdong, Chiny |

| Nazwa handlowa: | Uchi |

| Orzecznictwo: | SMC |

| Numer modelu: | zanurzeniowa płyta chłodząca-63 |

Zapłata:

| Minimalne zamówienie: | 100pcs |

|---|---|

| Cena: | negocjowalne |

| Zasady płatności: | T/T, PayPal, Western Union, Moneygram |

| Możliwość Supply: | 50000000 pCS miesięcznie |

|

Szczegóły informacji |

|||

| Tworzywo: | AL6063 | Rozmiar: | 40 mm x 200 mm x 12 mm |

|---|---|---|---|

| Waga (kg): | 15 | Funkcja: | Dobra zdolność chłodzenia i brak domyślnych wycieków |

| Obróbka powierzchniowa: | oczyszczony olejem, oczyszczony i pasywowany | Orzecznictwo: | CE,16949 |

| Podkreślić: | miedziany radiator chłodzony wodą z rurkami,płyta chłodząca zanurzeniowa ciecz,miedziana płyta chłodząca cieczą |

||

opis produktu

Płytka chłodząca przez zanurzenie ogrzewacza chłodzonego wodą z rury miedzianej

Opis produktu

Jako profesjonalny producent rozwiązań chłodzących sprzętu laserowego z rurki miedzianego wody, dostarczamy wysokiej jakości płyty chłodne z niezawodną usługą posprzedażną i terminową dostawą.

Zalety produktu

- Udowodnione doświadczenie w dostarczaniu głównych klientów krajowych, w tym Han's Laser

- Współpraca z Huazhong Technological University w zakresie zaawansowanego rozwoju płyt chłodzących

- Specjalizujemy się w wytwarzaniu grubej płyty zimnej o wysokiej mocy chłodzenia dla nowoczesnych maszyn laserowych

Specyfikacja produktu

| Specyfikacja | Szczegóły |

|---|---|

| Nazwa produktu | Zindywidualizowane |

| Numer części | Zindywidualizowane |

| Obsługa powierzchni | Nikkel, malowanie, przeciwutleniacz |

| Proces | Stamping, obróbka CNC, perforacja, wiercenie, szczelinowanie, skasowanie, lutowanie, frezowanie |

| Materiał | Aluminium i miedź |

| Wymiar | Zindywidualizowane |

| Zastosowanie | Centrum danych, IGBT, sprzęt medyczny, wysokiej mocy światło LED, Inwerter słoneczny, chłodzenie TEC |

Zdolności produkcyjne

Nasze 5-panełowe maszyny CNC umożliwiają wysoką wydajność produkcji z pięcioma programowalnymi procesami w jednym etapie.

Siła badań i rozwoju

- Inżynierowie z Południowochińskiego Uniwersytetu Technologicznego i Huazhong University of Science and Technology

- Z możliwością produkcji płyt chłodzących wodą o grubości 0,5 mm o mocy chłodzącej 700 W

- Zespół 10 inżynierów, w tym 3 z doświadczeniem w międzynarodowych przedsiębiorstwach

Pojemność produkcyjna

- Chłodniki CPU: 50 000 sztuk/miesiąc

- Płyty chłodzące wodą z rur cieplnych: 12 500 sztuk/miesiąc

- Rury cieplne: 150 000 sztuk/miesiąc

- Obecnie rozbudowana produkcja

Wyniki sprzedaży

- Obrot miesięczny: ~ 4 mln (godzień szczytowy przekracza 7 mln)

- Roczna wielkość obrotu: 70-80 mln

Sprzęt produkcyjny

- 25 Maszyny CNC

- 10 maszyny do pieczętowania

- 2 maszyny do spawania tarciem

- 2 duże dmuchawy termiczne

- 4 maszyny do cięcia drutu

- 2 maszyny z iskry

- 4 frezarki

- 3 szlifowania

Wyposażenie do badań

- 1 Maszyna pomiarowa współrzędna

- 1 przyrząd projekcyjny

- 2 maszyny do badania wysokiego ciśnienia wody

- 4 maszyny do badania odporności termicznej

- 2 maszyny do badania wycieku płynu

Linia montażowa lutownictwa

Nasz zespół

- Zespół współpracujący z silną jednością

- Wysoka wydajność i ciągły rozwój

- Odpowiedzialność rynkowa z dużą zdolnością adaptacyjną

Nasze certyfikaty

Nasze usługi

- Szybka odpowiedź na zapytania

- Produkty wysokiej jakości w konkurencyjnych cenach

- Skuteczne planowanie produkcji w celu terminowej dostawy

- Optymalne rozwiązania transportowe oparte na specyfikacjach produktu

- Kompleksowe wsparcie techniczne w przypadku wszelkich problemów z produktem

Częste pytania

P: Czy jest pan firmą handlową lub producentem?

A: Jesteśmy profesjonalnym producentem z dużym doświadczeniem w produkcji płyt chłodniczych i chłodzących wodą, z zautomatyzowanymi i zmechanizowanymi procesami produkcyjnymi.

P: Czy wcześniej eksportowałeś towary i do jakich regionów?

Odpowiedź: 60% naszej produkcji jest eksportowane na całym świecie, w tym do Japonii, Indii, Wielkiej Brytanii, Kanady, USA i Brazylii.

P: Ilu masz pracowników?

Odpowiedź: Nasza siła robocza licząca około 100 osób obejmuje dział sprzedaży, zakupów, inżynierii, kontroli jakości, magazynu i produkcji.

P: Czy możesz dostarczyć próbki, jeśli zgadzamy się z projektem?

O: Tak, dostarczamy próbki do potwierdzenia przed masową produkcją i możemy dostarczyć rysunki techniczne w razie potrzeby.

P: Jakie metody pakowania stosujecie w celu zapewnienia bezpieczeństwa?

Odpowiedź: Wykorzystujemy opakowania na zamówienie, w tym standardowe kartony z tkaniną ochronną i drewniane skrzynki dla optymalnego bezpieczeństwa transportu.

P: Czy zapewniacie wsparcie techniczne w przypadku problemów z produktami?

Odpowiedź: Wszystkie produkty są dokładnie sprawdzane przed wysyłką.

Chcesz dowiedzieć się więcej o tym produkcie