RoHS High Energy Electronic MOV / TMOV 20D For SPD , Metal Oxide Varister

Szczegóły Produktu:

| Place of Origin: | Dongguan,Guangdong,China |

| Nazwa handlowa: | UCHI |

| Orzecznictwo: | UL.VDE,SGS,REACH,CQC,CSA.ISO.ROHS,CUL |

| Model Number: | TMOV 20DT331K |

Zapłata:

| Minimum Order Quantity: | 5000PCS |

|---|---|

| Cena: | negocjowalne |

| Packaging Details: | Bulk |

| Delivery Time: | 5-7 days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 5000,000,000PCS Per Month |

|

Szczegóły informacji |

|||

| Podkreślić: | mov metal oxide varistor,metal oxide varistor mov |

||

|---|---|---|---|

opis produktu

RoHS High Energy Electronic MOV / TMOV 20D For SPD , Metal Oxide Varister

Quick Detail:

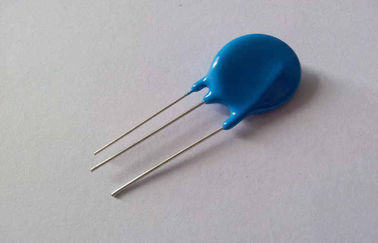

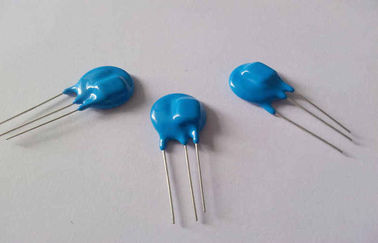

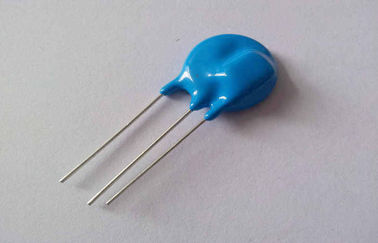

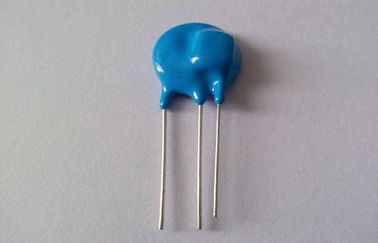

1)RoHS compliant and Lead–free available

2)Patented integrated thermal protection device

3)Designed to facilitate compliance to UL1449 3nd Edition for SPD product

4)High peak surge current rating up to 10kA

5)Wave solderable

6)Standard lead form and spacing option

7)Low leakage

8)-55°C to +85°C operating temp range

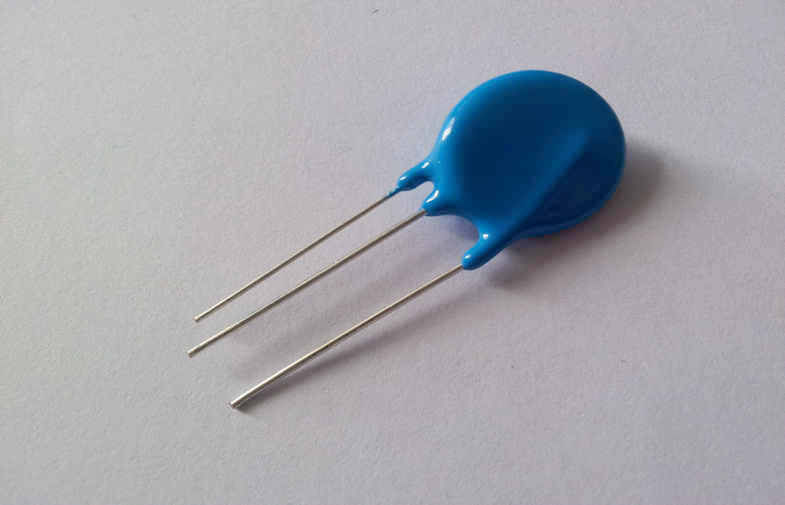

9)Three-lead version available for indication purposes

Description:

TMOV thermally protected varistors represent a new development in integrated circuit protection. Both versions are comprised of radial leaded MOVs (Metal Oxide Varistors) with an integrated thermally activated element designed to open in the event of overheating due to the abnormal overvoltage, limited current, conditions outlined in UL 1449.

The iTMOV varistor differs from the varistor by the inclusion of a third party lead for the purpose of indicating that the MOV has been disconnected from the circuit. This lead facilitates connection to monitoring circuitry.

- The TMOV varistors offer quick thermal response due to the close proximity of the integrated thermal element to the MOV body.

- The integrated configuration also offers lower inductance than most discrete solutions resulting in improved clamping performance to fast over-voltage transients.

Additionally, TMOV varistors are wave solderable, thus simplifying end product assembly by reducing the expense and rework associated with hand soldering operations.

- The TMOV varisors are both recognized surge suppression components to UL 1449.

- The TMOV varistor’s integrated thermal element, in conjunction with appropriate enclosure design, helps facilitate TVSS module compliance to UL 1449 for both cord connected and permanently connected applications.

- TMOV and iTMOV varistors are compatible for use with industry standard wave-soldering processes or recommended hand-soldering methods.

Applications:

• SPD Products

• AC Panel Protection Modules

• AC Line Power Supplies

• Surge Protected Strip Connectors

• AC Power Meters

• Relocatable AC Power Taps

• GFCI (Ground Fault CurrentInterupter)

• UPS (Uninterruptable Power Supply)

• White Goods

• Plug-in SPD

• Inverters

• AC/DC Power Supplies

Specifications:

|

Type |

Your Ref. |

Material No. |

Design |

Version |

|

TMOV20DT331K |

|

20DT331K |

TMOV |

PAGE 1 OF 2 |

|

Physical parameters |

Unit : mm |

||||||

|

|

D (max.) |

25.0 |

|||||

|

H2 (max.) |

29.0 |

||||||

|

T (max.) |

9.5 |

||||||

|

L (min) |

20.0 |

||||||

|

l (min) |

15.0 |

||||||

|

W1 (±1.0) |

7.5 |

||||||

|

W2 (±1.0) |

4.0 |

||||||

|

e1 (max) |

2.7 |

||||||

|

e2 (max) |

4.3 |

||||||

|

d1 (±0.1) |

1.0 |

||||||

|

d2 (±0.1) |

0.8 |

||||||

|

Lead wire |

Tinning copper wire |

||||||

|

R |

Comply with ROHS Directive |

||||||

|

Coating |

Blue insulated epoxy resin |

Weight |

6.7g |

||||

|

Electrical parameters |

|||||||

|

Varistor voltage (V1mA) |

297V |

~ |

330 V |

~ |

363V |

||

|

Max. continuous operating voltage |

Vrms: 210 V; |

VDC: 275V |

|||||

|

Rated power |

1.0 W |

||||||

|

Max. clamping voltage (8/20μs) |

VC: 550V; |

IC: 100A |

|||||

|

Surge current (1×8/20μs) |

8000 A |

(8/20μs) |

|||||

|

Max. energy |

110 J |

(2ms) |

|||||

|

Typical capacitance |

1750pF |

(1KHz) |

|||||

|

Leakage current |

≦10μA |

(75% of V1mA (DC)) |

|||||

|

Operating temperature |

-40℃ ~ +85℃ |

||||||

|

Storage temperature |

-40℃ ~ +100℃ |

||||||

|

Fuse temperature |

146℃ |

||||||

|

Hand soldered temperature / Time |

265℃/3s |

||||||

|

Packing |

■ |

Bulk |

200pcs/bag |

800pcs/box |

1600pcs/carton |

|

□ |

Tape&Reel |

----pcs/reel |

------pcs/box |

------pcs/carton |

|

|

□ |

Ammopack |

----pcs/bag |

-------------------- |

------pcs/carton |

SPECIFICATION FOR APPROVAL

|

PAT NO. |

20DT331K |

PAGE 2 OF 2 |

|||||

|

DATE: 2012-3-17 |

|||||||

|

3.Mechenical Requirements |

|||||||

|

3.1 |

Tensile of Terminations |

No Outstanding Damage |

1Kgf; 10Sec. |

||||

|

3.2 |

Bending of Terminations |

No Outstanding Damage |

0.5Kgf; 90∘ ,3 Times |

||||

|

3.3 |

Vibration |

No Outstanding Damage |

Freq:10-55hz; Amp: 0.75mm,1Min. |

||||

|

3.4 |

Solderability |

Min. 95% of The Terminal Should Be Covered With Solder Uniformly |

Solder Temp:265±5℃ Immersed Time: ≦5Sec. |

||||

|

3.5 |

Resistance of soldering heat |

△ V1mA/V1mA ≦±5% |

Solder Temp: 260±5℃ |

||||

|

Immersed Time: 10±1Sec. |

|||||||

|

4.Enviromental Requirements |

|||||||

|

4.1 |

High Temperature Storage |

△V1mA/V1mA ≦±5% |

Ambient Temp: 125±2℃ Duration:1000h |

||||

|

4.2 |

Low Temperature Storage |

△V1mA/V1mA ≦±5% |

Ambient Temp: -40±2℃ Duration:1000h |

||||

|

4.3 |

High Humidity Storage/Damp Heat |

△V1mA/V1mA ≦±5% |

Ambient Temp: 40±2℃ 90-95% R.H. Duration: 1000h |

||||

|

4.4 |

Temperature Cycle |

△V1mA/V1mA ≦±5% |

Step |

Temperature |

Period |

||

|

1 |

-40℃ |

30 min |

|||||

|

2 |

Room Temp |

15 min |

|||||

|

3 |

125℃ |

30 min |

|||||

|

4 |

Room Temp |

15 min |

|||||

|

4.5 |

High Temperature Load |

△V1mA/V1mA ≦±10% |

Ambient temp:85±2℃ Duration:1000h Load: MAx. Allowable Voltage |

||||

|

4.6 |

High Humidity Load |

△V1mA/V1mA ≦±10% |

Ambient Temp:125±2℃ Duration:1000H Load: MAX. Allowable Voltage |

||||

|

4.7 |

Operating Temperature Range |

-40℃ ~ +85℃ |

-40℃ ~ +85℃ |

||||

|

4.8 |

Storage Temperature Range |

-40℃ ~ +125℃ |

-40℃ ~ +125℃ |

||||

|

Part Number |

Acrms(V) |

DC(V) |

V1.0 mA(V) |

VC(V) |

IP(A) |

1 time(A) |

2 time(A) |

10/1000μA |

2ms |

(W) |

(A) |

@1KHz(Pf) |

|

20D(F,T)820K |

50 |

65 |

82(74-90) |

135 |

100 |

6500 |

4500 |

56 |

42 |

1.0 |

15 |

4900 |

|

20D(F,T)101K |

60 |

85 |

100(90-110) |

165 |

100 |

6500 |

4500 |

70 |

52 |

1.0 |

15 |

4000 |

|

20D(F,T)121K |

75 |

100 |

120(108-132) |

200 |

100 |

6500 |

4500 |

85 |

63 |

1.0 |

15 |

3300 |

|

20D(F,T)151K |

95 |

125 |

150(135-165) |

250 |

100 |

10000 |

8000 |

100 |

70 |

1.0 |

15 |

2700 |

|

20D(F,T)181K |

115 |

150 |

180(162-198) |

300 |

100 |

10000 |

8000 |

110 |

80 |

1.0 |

15 |

2200 |

|

20D(F,T)201K |

130 |

170 |

200(185-225) |

340 |

100 |

10000 |

8000 |

140 |

100 |

1.0 |

15 |

2000 |

|

20D(F,T)221K |

140 |

180 |

220(198-242) |

365 |

100 |

10000 |

8000 |

155 |

110 |

1.0 |

15 |

1800 |

|

20D(F,T)241K |

150 |

200 |

240(216-264) |

395 |

100 |

10000 |

8000 |

170 |

120 |

1.0 |

15 |

1650 |

|

20D(F,T)271K |

175 |

225 |

270(243-297) |

455 |

100 |

10000 |

8000 |

190 |

135 |

1.0 |

15 |

1500 |

|

20D(F,T)301K |

190 |

250 |

300(270-330) |

500 |

100 |

10000 |

8000 |

205 |

145 |

1.0 |

15 |

1300 |

|

20D(F,T)331K |

210 |

275 |

330(297-363) |

550 |

100 |

10000 |

8000 |

215 |

150 |

1.0 |

15 |

1200 |

|

20D(F,T)361K |

230 |

300 |

360(324-396) |

595 |

100 |

10000 |

8000 |

225 |

160 |

1.0 |

15 |

1100 |

|

20D(F,T)391K |

250 |

320 |

390(351-429) |

650 |

100 |

10000 |

8000 |

240 |

170 |

1.0 |

15 |

1000 |

|

20D(F,T)431K |

275 |

350 |

430(387-473) |

710 |

100 |

10000 |

8000 |

270 |

190 |

1.0 |

15 |

930 |

|

20D(F,T)471K |

300 |

385 |

470(423-517) |

775 |

100 |

10000 |

8000 |

350 |

250 |

1.0 |

15 |

850 |

|

20D(F,T)511K |

320 |

415 |

510(459-561) |

845 |

100 |

10000 |

8000 |

380 |

270 |

1.0 |

15 |

780 |

|

20D(F,T)561K |

350 |

460 |

560(504-616) |

920 |

100 |

10000 |

8000 |

400 |

280 |

1.0 |

15 |

710 |

|

20D(F,T)621K |

385 |

505 |

620(558-682) |

1025 |

100 |

10000 |

8000 |

425 |

300 |

1.0 |

15 |

650 |

|

20D(F,T)681K |

420 |

560 |

680(612-748) |

1120 |

100 |

10000 |

8000 |

435 |

310 |

1.0 |

15 |

600 |

|

20D(F,T)751K |

460 |

615 |

750(675-825) |

1240 |

100 |

10000 |

8000 |

455 |

327 |

1.0 |

15 |

530 |

|

20D(F,T)781K |

485 |

640 |

780(702-858) |

1290 |

100 |

10000 |

8000 |

461 |

335 |

1.0 |

15 |

510 |

|

20D(F,T)821K |

510 |

670 |

820(738-902) |

1355 |

100 |

10000 |

8000 |

475 |

344 |

1.0 |

15 |

500 |

|

20D(F,T)911K |

550 |

745 |

910(819-1001) |

1500 |

100 |

10000 |

8000 |

500 |

350 |

1.0 |

15 |

440 |

|

20D(F,T)102K |

625 |

825 |

1000(900-1100) |

1650 |

100 |

10000 |

8000 |

560 |

400 |

1.0 |

15 |

400 |

|

20D(F,T)112K |

680 |

895 |

1100(990-1210) |

1815 |

100 |

10000 |

8000 |

610 |

430 |

1.0 |

15 |

360 |

|

20D(F,T)122K |

700 |

990 |

1200(1080-1320) |

1880 |

100 |

10000 |

8000 |

650 |

460 |

1.0 |

15 |

320 |

|

20D(F,T)180K |

11 |

14 |

18(15-21.6) |

36 |

20 |

3000 |

2000 |

13 |

10 |

0.2 |

5 |

28500 |

|

20D(F,T)220K |

14 |

18 |

22(19.5-26) |

43 |

20 |

3000 |

2000 |

16 |

12 |

0.2 |

5 |

18500 |

|

20D(F,T)270K |

17 |

22 |

27(24-31) |

53 |

20 |

3000 |

2000 |

19 |

14 |

0.2 |

5 |

13000 |

|

20D(F,T)330K |

20 |

26 |

33(29.5-36.5) |

65 |

20 |

3000 |

2000 |

24 |

18 |

0.2 |

5 |

11500 |

|

20D(F,T)390K |

25 |

31 |

39(35-43) |

77 |

20 |

3000 |

2000 |

28 |

21 |

0.2 |

5 |

8500 |

|

20D(F,T)470K |

30 |

38 |

47(42-52) |

93 |

20 |

5000 |

3000 |

34 |

25 |

0.2 |

5 |

7400 |

|

20D(F,T)560K |

35 |

45 |

56(50-62) |

110 |

20 |

5000 |

3000 |

41 |

30 |

0.2 |

5 |

6500 |

|

20D(F,T)680K |

40 |

56 |

68(61-75) |

135 |

20 |

5000 |

3000 |

49 |

37 |

0.2 |

5 |

5800 |

Competitive Advantage:,

- Factory supply directly

- Completed certificates such as UL,VDE,SGS,etc and high quality available

- Quick delivery

- Best after-sales services

- OEM & ODM available

![]()